WaveTopSign CNC Controller TAC-1005M for Metal Cutter Spindle

Control axis:

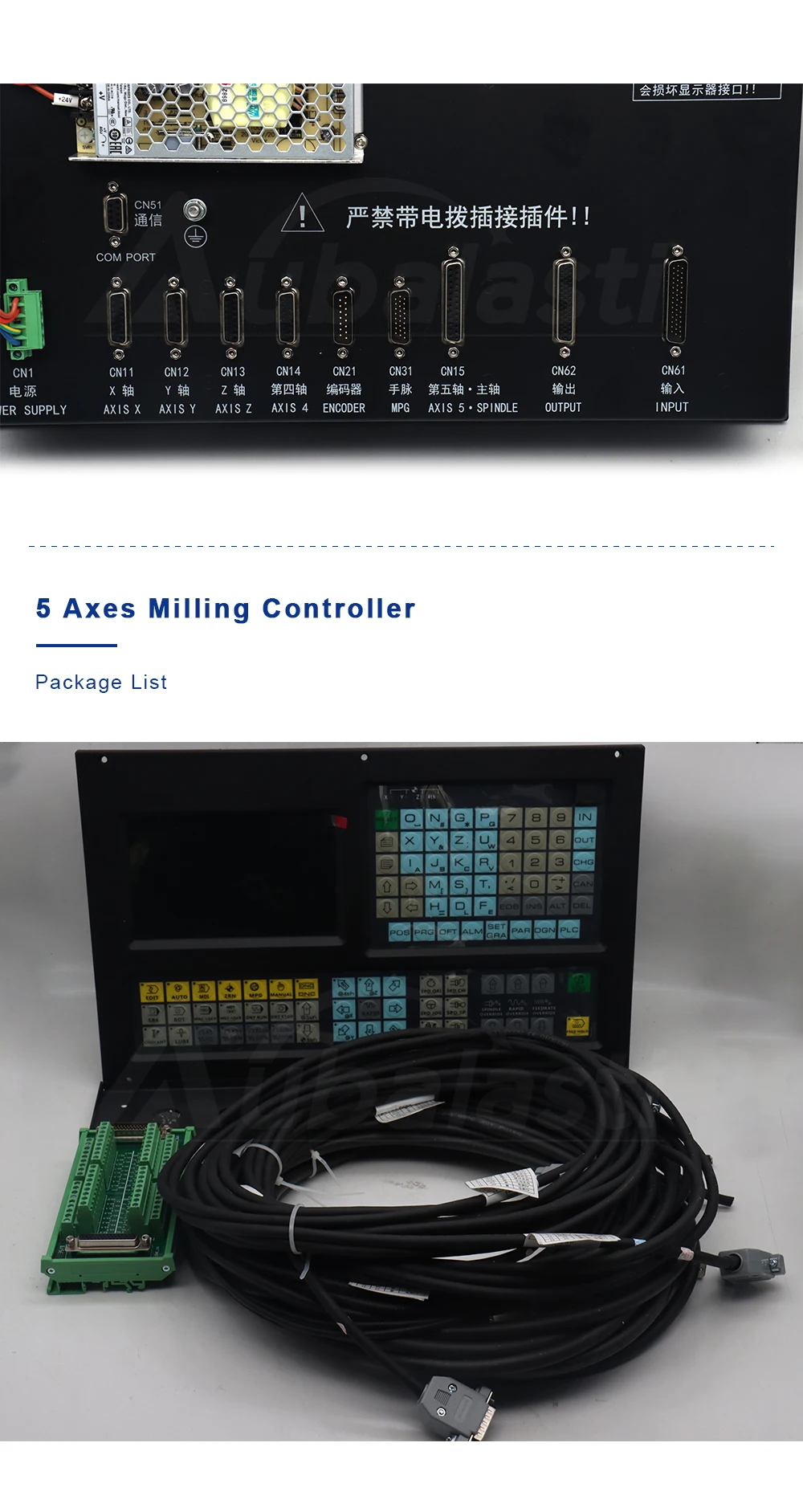

● Control axis: 5 axis (X, Y, Z,4th,5th)

● Linkage axis: 5 axis Feeding axis functions

● Position command range:

Metric input (G21) -9999.9999mm ~9999.9999mm, the mininum command unit: 0.0001mm

Inch input (G20): -999.9999inch ~999.9999inch, the mininum command unit:0.0001inch

● Electronic gear ration: command multiplier 1 ~ 65536, command multiplier1 ~65536

● Rapid traverse speed: maximum 60m/min

● Rapid traverse override: F0, 25%, 50%, 100% four levels real-time tuning

● Cutting feedrate: maximum feeding speed: maximum 15m/min (G94) or 500.00mm/r (G95)

● Feedrate override: 0 ~ 150% sixteen-level real-time tuning

● Manual feedrate: 0 ~ 150% sixteen-level real time tuning

● MPG feeding: 0.001mm, 0.01mm, 0.1mm, 1mm four gears

● Single step feeding: 0.001mm, 0.01mm, 0.1mm, 1mm four gears

● Interpolation mode: linear interpolation, arc interpolation, spiral interpolation and ragid rapping

● Automatic chamfering function

Acceleration/deceleration types:

● Cutting feeding: before the acceleration and deceleration linear type, before the acceleration and deceleration Stype, after the acceleration and deceleration linear type and after the acceleration and deceleration index type.

● Fast moving: before the acceleration and deceleration linear type, before the acceleration and deceleration S type, after the acceleration and deceleration linear type and after the acceleration and deceleration index type.

●System with preview function, it can read 15 NC programming, make small line interpolation in high speed and smooth, it’s suit for components machine toolings processing.

● The original speed of acceleration and deceleration, end speed and acceleration & deceleration speed set by parameters.

● Manual mode, handwheel mode is after acceleration and deceleration control, handwheel mode can choose emergency mode or full operation mode.

● Rapid positioning can choose linear or broken line.

Spindle axis functions:

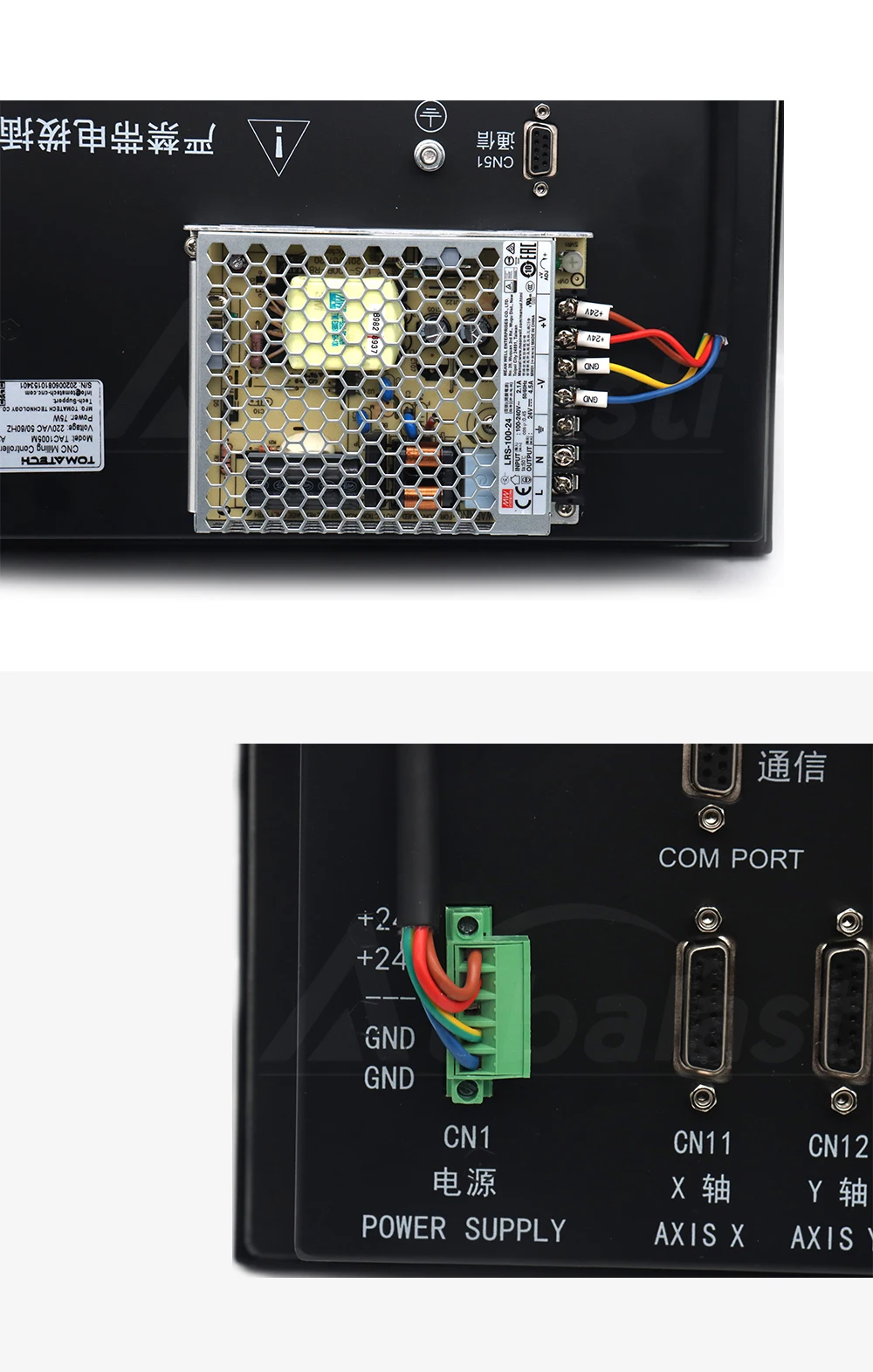

● Two channels -10V ~ 10V analog voltage output, support double spindle control

● Spindle encoder: encoder lines can be set (100 p/r ~ 5000p/r)

● Encoder and spindle’s transmission ratio: (1 ~ 255):(1 ~ 255)

● Spindle ration: 50% ~ 120% eight stages real-time tunning in total

● Spindle axis constant line speed control

● Tapping circle, rigid tapping

Tool functions:

● Tool length compensation

● Tool point radius compensation (C type)

Precision compensation:

●Thread pitch error compenstation: Compensation points, compensation interval, compensate original position can be set.

●Backlash compensation: can set reverse interval to interpolation machine tool by fixed frequency or lifting speed mode.

PLC functions:

● Two levels PLC programming, operation speed is 1.5μs/ step basic instruction; 4700 steps mostly, the cycle of the first level programming is 8ms.

● Support PLC warning and PLC alarm.

● Support multiply PLC programming (mostly 20), the current PLC programming can be chosen.

● 45 kinds of commands (10 kinds of basic commands, 35 kinds of function commands)

● I/O unit input/output: 36/36

Display interface:

● 7.0 inch wide-screen LCD, 800×480 lattice

● Chinese, English etc multiply language display

● 2D tool path displays.

● Real-time clock

Operation mode:

● Operation modes: edit, automatic, input, machine tool reset, handwheel/single-step, manual, DNC.

● Multiple operateauthority management.

● Alarm logging

Program edit:

● Program volumn: 56MB, it can store 400 programmings mostly (includes sub-programming, Marco programming)

● Edit function: Programming/programming segment/word retrieval, amend, delete, copy, and stick

● Programming format: ISO code,supports statement macro program, supports relative coordinate, absolute coordinate and polar coordinate.

● Programming calls: supports maco with parameters calls, level 4 subprogram nesting.

Communication function:

● RS232: parts program, parameters and some documentation two-way transmission, supports PLC program, system software serial ports update.

● USB: U disk documentation operatiom, U disk processing directly, Support PLC program, system software U disk update.

● Support serial port DNC processing function and USB online processing function, reliability and safty Relability and safty function

● Emergency stop

● Handware route limit

● Software routet inspect

● Data backups and Data recover.

We typically ship in 1-3 business days (Mon-Fri). And you will receive your order in 10-15 business days (Mon-Fri). Please know that we are doing the best we can to get orders out promptly.

We send FEDEX by default.

If you need to change other logistics, you can contact customer service.

When your order ships you will receive a separate email providing you with a tracking number to track your order. Sometimes this email gets sorted into spam or promotions folders so be sure to take a look in there if it feels like you have been waiting a little too long.

You can also log into your account and click on the order in question to see the status.

*Please note that sometimes the tracking can take a day or two to be updated by the carrier. If it looks like its not moving, chances are its on its way!

OUR PRODUCTS

Attention! Deal Zone

Featured Products

About us

Contact us

Your Suggestion

Corporate Philosophy

Privacy policy

Terms of Use

Customer Care

My Account

Track your Order

Customer Service

Returns/Exchange

Product Support

© 2022 Pext - All Rights Reserved.