Introduction:

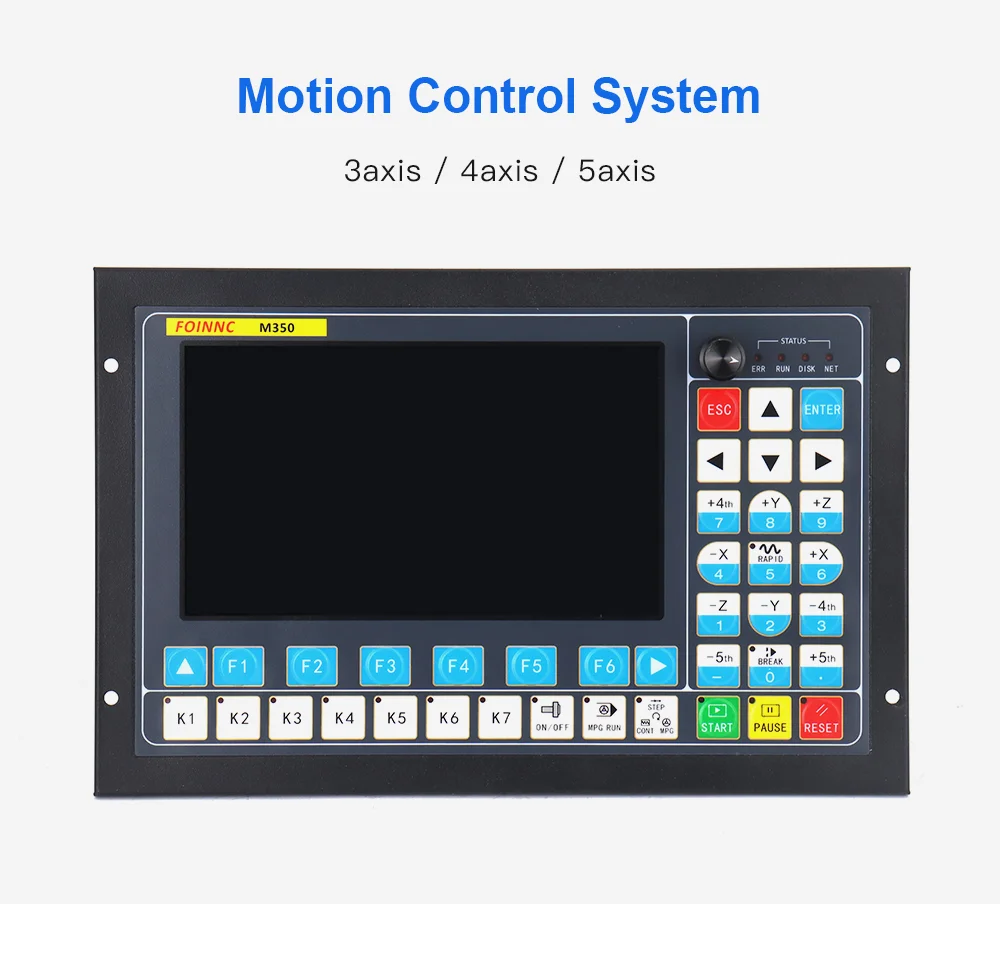

System M350 is a professional 3-5 axis motion controller based on embedded platform. It is equipped with a 7-inch full-color screen, complete keyboard input and customizable function keys to make user operations more convenient. It supports multi-process, linear tool magazine, and disc tool magazine functions. The interface and structure adopt the mainstream methods on the market, which are simple to operate, easy to learn and understand, and easy to install. The system adopts advanced adaptive speed forward control algorithm, which has the characteristics of high processing efficiency and good surface quality. Meet the needs of various engraving machines, engraving milling machines, and cutting machines.

Parameters:

* Max. number of control axis: M350 3-5axis, 2-5 linear interpolation, arbitrary 2-axis circular interpolation;

* Operation mode: mainstream engraving machine system operation;

* Display Size: 7 / 10.2 inches;

* Display Resolution: 1024x600;

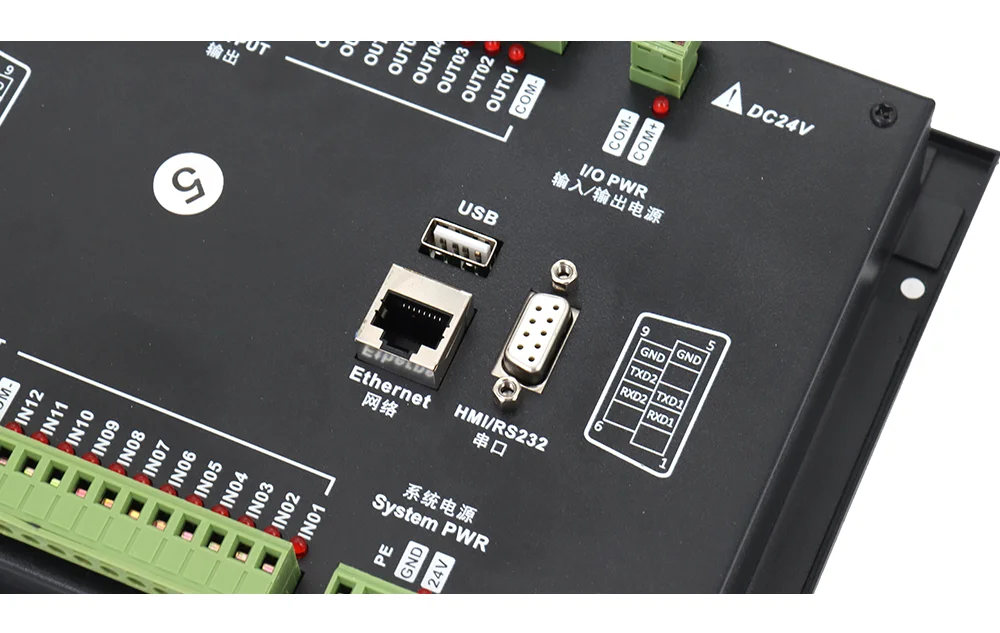

* I/O: M6xx Standard IO 20/21, M3xx standard IO 24/21;

* Analog Voltage Output: 0-10V;

* PWM Output: only supports M3xxz

* Tool Magazine Type: multi-process, in-line, disc;

* Tool Setting Mode: support automatic and manual tool setting;

* Tool Setting Type: fixed tool setting, floating tool setting, first tool setting/second tool setting;

* Compensation Methods: direction gap compensation, radius compensation, length compensation;

* Interpolation Algorithm: S shape, hard arc algorithm, soft arc algorithm;

* Language: Support Chinese and English;

* CNC Software Alarm: program error, operation error, overtravel error, servo drive alarm, etc.;

* Network: Support file sharing and remote file online processing;

* Open Collector Output, the maximum output current is 500mA, which can directly drive the relay;

* The pulse direction adopts differential output, and the maximum interpolated pulse output frequency is 1MHZ;

* Spindle Control Mode: multi-speed (4 speed, 16 speed), analog quantity (0-10v), servo spindle;

* Compatible with standard G codes. Support mainstream CAD/CAM software, such as ArtCam, MasterCam, ProE, etc.

* The user interacts with external files through the U disk and works completely offline;

* Multi-stage preprocessing, adaptive speed forward control of the processing track, fast processing speed, high precision, and good processing continuity;

* Continuously process small line segments at high speed, and automatically select the most effective algorithm among various small line segment control algorithms;

* Support large-capacity file processing;

* With breakpoint memory, automatic power-off protection function, near-point processing function and designated line processing function;

* Support time lock function;

* Support four operation permissions (guest, operator, administrator, super administrator);

* With automatic return to origin, return to origin, workpiece origin saving and loading functions;